Shakshat Virtual Lab

INDIAN INSTITUTE OF TECHNOLOGY GUWAHATI

CLICK HERE TO SEE THE VIRTUAL WORKSHOP

INTRODUCTION :

The distillation column consists of several trays, which allow the simultaneous travel of liquid down the tray and vapor up the tray, allowing mixing of the two phases and therefore equilibrium.

The liquid mixture that is to be processed is known as the feed. The feed-tray divides the column into a top (enriching or rectifcation) section and a bottom (stripping) section.

The vapour moves up the column,and as it exits the top of the unit, it is cooled by a condenser. The condensed liquid is stored in a holding vessel known as the reflux drum.Some of this liquid is recycled back to the top of the column and this is called the reflux.

The condensed liquid that is removed from the system is known as the top product or distillate.

DESIGN OF DISTILLATION COLUMN :

The accurate design of distillation columns is a very important topic in chemical industry. Here we describe a Mathematical program for the design of distillation columns for binary mixtures.

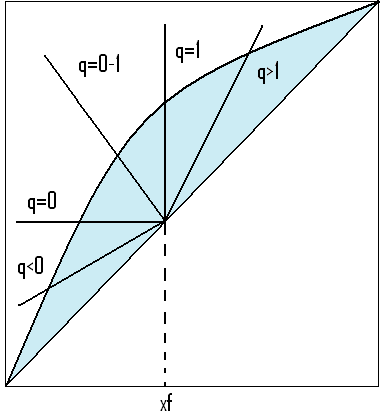

For simplicity,it is assumed that the columns are designed by following McCabe-Thiele�s procedure, a graphical method which determines both the number of stages required for the desired degree of separation and the location of the feed tray .

The detailed diagram is shown in figure.McCabe-Thiele�s method also requires some additional assumptions.In particular, it is assumed that:

(1) the molar overflow is constant.

(2) the molal heats of vaporization of the components are roughly the same

(3) heat effects are negligible.

FIG 2.2