Shakshat Virtual Lab

INDIAN INSTITUTE OF TECHNOLOGY GUWAHATI

DIAMETER CALCULATIONS :

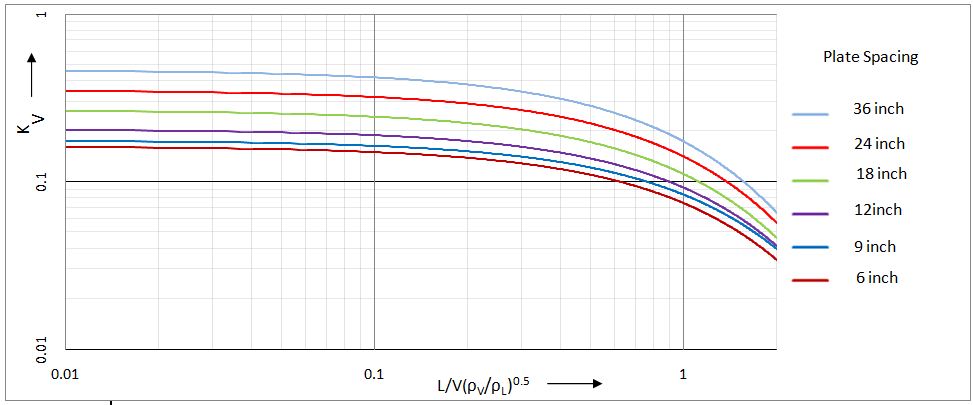

For diameter calculations initially we begin with the calculations of physical properties of feed components. Then we go for vapor velocity calculation as shown in eqn 1. A correlation that includes the effect of surface tension is given below; values of Kv for use with this equation are shown in Fig 1. The correlation is not recommended for liquids of very low surface tension or for systems that foam easily using the value of kv the allowable vapor velocity uc can be determined using eqn1.

........................eqn (2.3)

........................eqn (2.3)

Then the vapor flow rate can be further calculated using eqn 2 .

.......................eqn (2.4)

.......................eqn (2.4)

The cross sectional area of the column can be determined by calculating the bubbling area and the column area. Bubbling area = (vapor flow rate /allowable vapor velocity). If the bubbling area is 70% of the total column area then column area = bubbling area / 0.7 . finally the column diameter can be calculated by using eqn 3.

.................................eqn (2.5)

.................................eqn (2.5)

Fig 2.4 gives the value of Kv at flooding conditions , L/V = Ratio of mass flow rate of liquid to vapor, u is in ft/s, and sigmais in dyne/cm).

COLUMN HEIGHT CALCULATIONS :

The height of a trayed column is calculated by multiplying the number of (actual) stages by the tray separation. Tray spacing can be determined as a cost optimum, but is usually set by mechanical factors. The most common tray spacing is 24 inches .It allows enough space to work on the trays whenever the column is big enough around (>5 ft diameter).

In addition to the space occupied by the trays, height is needed at the top and bottom of the column. Space at the top typically an additional 5 to 10 ft is needed to allow for disengaging space. The bottom of the tower must be tall enough to serve as a liquid reservoir.

Depending on our needs we will probably design the base for about 5 minutes of holdup, so that the total material entering the base can be contained for at least 5 minutes before reaching the bottom tray. The total of height added to the top and bottom will usually amount to about 15% or so added to that required by the trays.